Storing maize for Jonathan Kimuge had always been a major challenge. Every year, Kimuge on average harvested a maximum of 45 bags each weighing 90 kilogrammes, that on average fetched Sh3,000 per bag or a total of Sh135,000. However, he would end up losing Sh1,000 per bag due to poor storage of the grains, which amounted to total loss of Sh45,000.

“The loss took place between the harvesting and drying period,” explained the farmer from Ngata, Nakuru county. But his fortunes changed when he adopted the Metal Silo, a grain storage technology that has been effective for reducing post-harvest insect and pathogen losses in maize.

“In addition to savings made, I’ve since stopped using insecticides to destroy weevils and rodents,” explained Kimuge at a posho mill in Nakuru where grain is stored before being milled, adding, “I no longer have to sell my maize grains all at ago. I am now able to sell the grains later when prices stabilise.”

In Kenya, the area under cultivation for maize farming is estimated at 2.9 million acres. The crop is the country’s staple food. Hannah Oduor working for the Ministry of Agriculture in Nakuru says pests and diseases contribute to about 30 per cent pre-harvest and post-harvest losses.

“Pests include stem borers and the maize lethal necrosis disease posing a major challenge to maize production,” she said.

Due to lack of adequate appropriate grain storage technologies, farmers end up selling their maize soon after harvest, only to buy it back at more than double the price later in the season to meet their basic needs, resulting in poverty traps.

Entomologist, Muthambuki Kimondo suggests that technologies such as metal silo is what is needed to contain post-harvest losses in Kenya, where it is estimated that 10-30 per cent of durable products are lost annually.

“However, even with the right technologies, we lack meaningful incentives, affordable financing options, and necessary government policies to encourage farmers to adopt efficient practices,” said the entomologist.

Introduction of yet another technology to preserve grains was godsent for Elizabeth Mwikali from Makueni county, whose loss was compounded by the threat of attack by aflatoxin.

The loss of her entire harvest was massive and she almost gave up maize farming, but thanks to the bags she currently use to preseve harvested grain, she did not quit. Mwikali uses the Purdue Improved Crop Storage bags ( PICS) technology.

The bags provide a simple, low-cost method of reducing post-harvest loss for up to three years. Melinda Gates Foundation, alongside other partners since 2013, allocated funds to support the three phase Sh23.6m (US23.6m) grain preservation project.

PICS Supply Chain Manager, Jane Njiru says the bags technology cuts off oxygen, thus suffocating the pests. A PICS bag consists of two layers of polyethylene liners and a third layer made from woven polypropylene as opposed to the common woven bags.

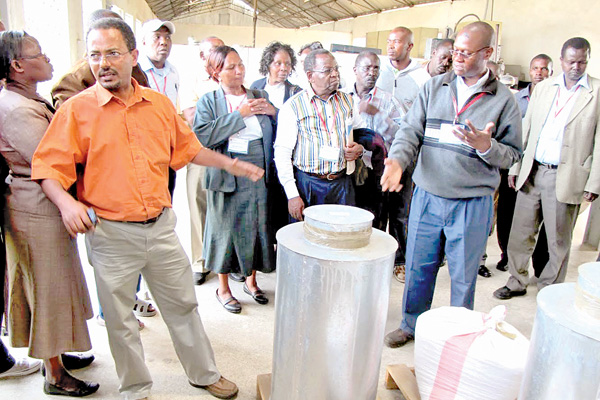

Kenya started manufacturing the bags since 2013. However, the leader of the PICS bags project, Purdue Research Associate Professor of Entomology Dr Dieudonné Baributsa, who was in town for a three-day workshop for manufacturers and distributors, said bags manufactured in Kenya are not accessible to the majority of small-holder farmers in rural areas outside urban and peri-urban centres.

If made affordable, more will access the bags. Kenya, which is an maize importer will become food secure and foreign exchange loss checked.

Article Source:http://www.mediamaxnetwork.co.ke/421805/new-storage-methods-curb-post-harvest-losses/